Back to Engineering

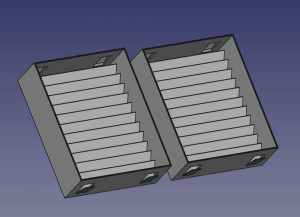

Now it’s onto mounting these things. Once the existing blocks are removed, the front plates get attached to a box that’s printed to fit and slipped in. Just two issues: how does the box get held in place, and let’s make sure those ugly raw blocks in the back are not visible. Since the holes are different sizes we need two boxes. The back of the plate already has slots to fit the box, all we need is a quick design.

Quick. I already mentioned “never say quick”, right? I never learn. These things turned into a crash course in industrial design. The projecting tabs are designed to hold the box in place, but in the first print, the attachment for the tab was too weak and one snapped with just a little push. The nice evenly spaced baffles on the back are ever so slightly different since the boxes are different heights. Another Python macro to the rescue! At least the prints were successful.

Fantastic! I absolutely love love love Mission style.

Thanks, Rawle! Another “couple of weeks” project that took a couple of years, but was worth it.